HOW DEEP LEARNING IS HELPING FACTORY AUTOMATION

The Power of Deep Learning

From the phones in our pockets to the reality of self-driving cars, the consumer economy has started to tap into the power of deep learning’s neural networks. This technology is now migrating into advanced manufacturing practices for quality inspection and other judgement-based uses. Deep learning-based image analysis combines the specificity and flexibility of human visual inspection with the reliability, consistency, and speed of a computerized system. Deep learning-based software can now perform judgement-based part location, inspection, classification, and character recognition challenges more effectively than humans or traditional machine vision automation. Increasingly, leading manufacturers are turning to deep learning solutions and artificial intelligence to solve their most sophisticated automation challenges.

How Deep Learning Helps Factory Automation

Deep learning-based image analysis combines the specificity and flexibility of human visual inspection with the reliability, consistency, and speed of a computerized system. Deep learning models can precisely and repetitively solve difficult vision applications that would be too complicated to program and frequently impossible to maintain using traditional machine vision approaches. Deep learning models can distinguish unacceptable defects while tolerating natural variations in complex patterns. And they can be readily adapted to new examples without re-programming their core algorithms.

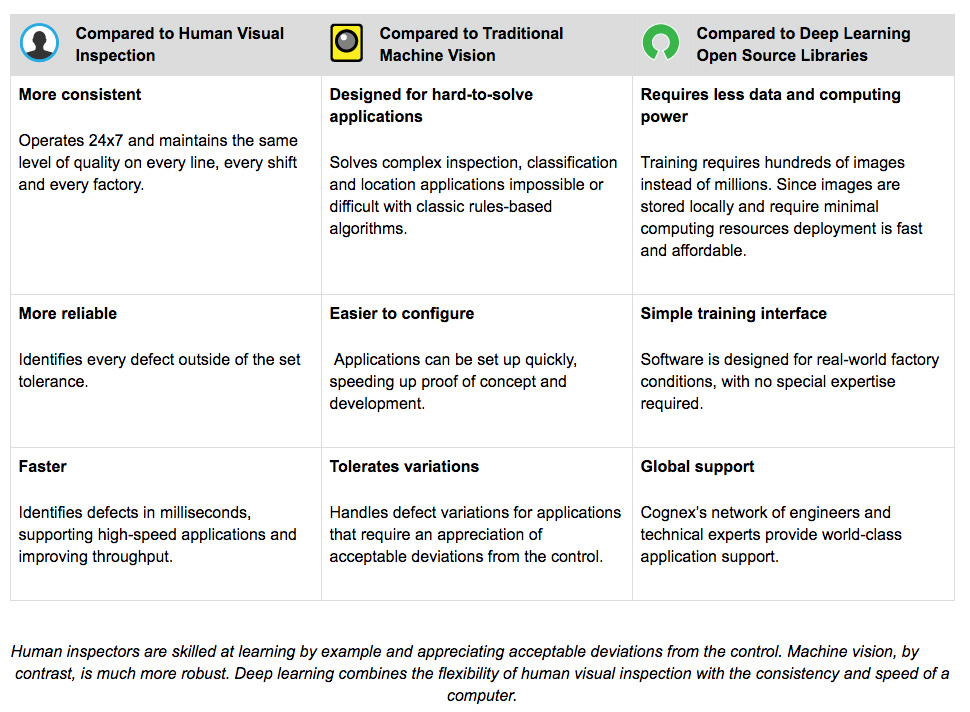

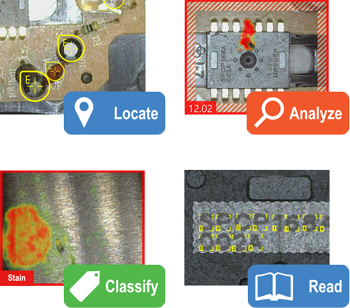

Deep learning-based software can now can perform judgment-based applications more effectively than humans or traditional machine vision solutions:

• Part location

• Inspection

• Classification

• Character recognition

Increasingly, leading manufacturers are turning to deep learning solutions and artificial intelligence to solve their most sophisticated automation challenges.

How Deep Learning Software Works

Deep learning software trains on a set of labeled images that represent a part’s known features, anomalies, and classes—much like a human inspector would be trained. A supervised training period teaches the system to recognize explicit defects. For defects that come in multiple forms, the system trains itself in unsupervised mode to learn the normal appearance of an object, including its significant but tolerable variations.

Based on these representative images, the software creates its reference model. It is an iterative process of constant improvement, during which parameters can be adjusted and the outcome validated until the model works as desired. During runtime, software extracts data from a new set of images, and its neural networks localize parts, extract anomalies, and classify them.

Advantages of Deep Learning

Deep learning expands the limits of what a computer and a camera can inspect

Deep learning has turned applications that previously required vision expertise into engineering challenges solvable by non-vision experts. Deep learning transfers the logical burden from an application developer, who develops and scripts a rules-based algorithm, to an engineer training the system. It also opens a new range of possibilities to solve applications that have never been attempted without a human inspector. In this way, deep learning makes machine vision easier to work with, while expanding the limits of what a computer and camera can accurately inspect.

What to learn more? Click the button below to contact one of our expects!