Laser scanners have been around forever. If you work for a company that makes something that someone else needs to buy, you probably have laser scanners at your facility.

The manufacturing industry has made a drastic shift towards image-based barcode readers (a.k.a. cameras) and has not looked back. If you haven’t gotten serious about taking a fresh look at your traceability technology, now is the perfect time.

Here are 4 strong reasons why you need to switch from laser scanners to cameras…

SAVING BIG WITH CONSUMER TECHNOLOGY

The most common misconception about cameras is that they are expensive. This may have been the case when the technology was in its infancy.

More recently, however, makers of image-based barcode readers have taken advantage of consumer electronics — you know, smartphones, tablets, etc. They all have high-end cameras and great processors. The technology easily translates to barcode readers. The cost of these components is very low, because they are sold in extremely high quantities. Chances are, your kids, friends, and family members are carrying around laser scanners. How many of them have at least one smart device, if not many?

When properly selected for the application, image-based barcode readers will have a lower upfront cost, a longer life with less maintenance (no moving parts), and better performance with less downtime, making your plant more profitable and driving down costs.

THE CHOICE OF INDUSTRY LEADERS

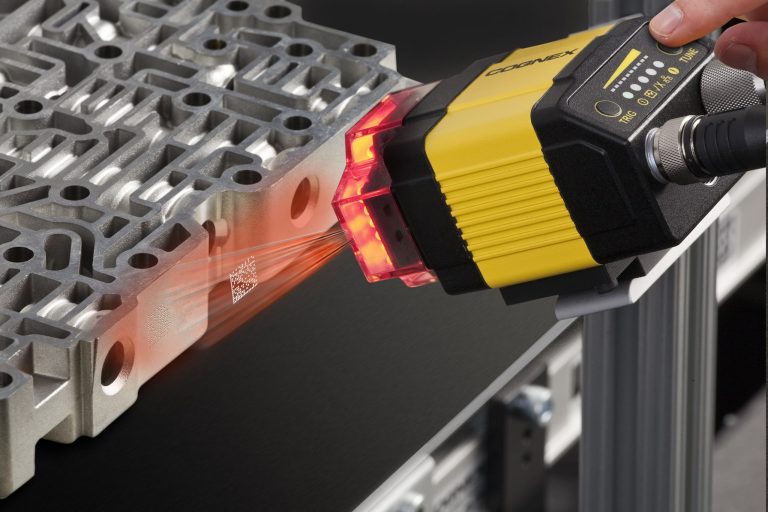

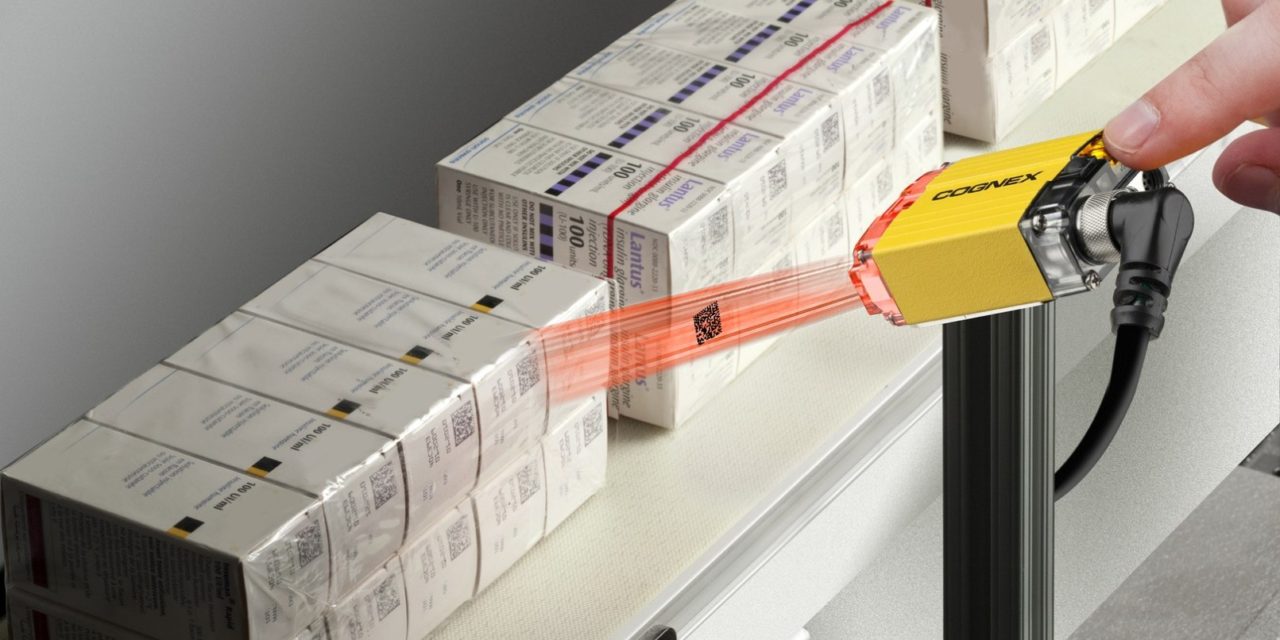

Just about every major player in the manufacturing world is replacing laser scanners with cameras. Name an industry: automotive, aerospace, logistics, retail distribution, food & beverage, pharmaceuticals, medical devices, electronics, and the list goes on. Think of the big players in these industries. Chances are, they have already made the switch to cameras for reading their barcodes. Why?

Cameras are no longer a new concept. They’ve reached maturity and have a proven track record of better performance and lower cost when compared to laser scanners. This concept has been proven time and time again.

2D CODES ARE EVERYWHERE

Imagine for a moment that you’re headed to the local big box with a shopping list.

Band-Aids, mouthwash, frozen lasagna, mint chocolate chip ice cream, and aspirin (sounds like a great weekend to me)

Take a closer look at the packaging. There is a 2D barcode on each of these items. 2D barcodes hold tons of information in a very small area. Marketing folks love 2D codes because they’re inconspicuous. They can embed lots of data on the box without taking away from the sexy graphics. Quality folks use them to serialize every single item. If there’s a recall, they can trace it down to the individual package, rather than a day’s/week’s/month’s worth of product. Executives love this, because smaller scale recalls generally mean less PR. VPs love brand protection.

2D codes are present in so many other aspects of your life, as well. If you have a newer model car, take a look at the individual components under the hood. 2D codes everywhere. Ever had surgery? They keep track of the reusable instruments’ sterilization records by reading a tiny 2D barcode laser-marked onto the instrument. No way is a big, “traditional” barcode going to fit on a scalpel, and a stick-on label can’t survive that environment. Are you obsessed with online shopping like my wife? More and more shipping labels now include 2D codes.

With the growing need for 2D codes, lasers are going by the wayside. They can’t read 2D codes at all. A image-based barcode reader is the only solution. Since cameras can read both 1D and 2D codes, it’s an obvious solution: cameras are the way to go.

TROUBLESHOOTING WITHOUT GUESSWORK

Your plant manufacturing line just shut down because of 5 missed barcode scans in a row.

How do you go about troubleshooting? Were the parts missing barcodes? Were the parts upside-down? Did someone walk in front of the reader and block its view of the line? Are the moving parts inside the laser scanner out of calibration, or broken?

Laser scanners lack any tangible feedback in this scenario. Engineers prefer cameras because they have the option of saving each picture they take. Even better, they can just save failed read attempts. This gives a real-life view of exactly what happened when the barcode reader missed a read, taking all the guesswork out of troubleshooting and getting your process back online faster.

MAKING THE SWITCH PAINLESSLY

The Proud Company represents Cognex, the industry leader in image-based barcode readers. We’ve deployed hundreds of systems and have the experience and expertise to help. Contact us today to see a demo and learn what the hype is all about!

Recent Comments